Background and Challenges

The development history of acoustic detection is long. It started with basic theoretical research such as sound velocity measurement and wave equation derivation. During World War I, acoustic ranging technology came into being. In the 1920s, sound level meters began to appear and gradually develop. In the 1960s, the application of transistor technology miniaturized and portabilized sound level meters. In the 1980s, the introduction of microprocessors gave them more functions. In the 21st century, sound level meters have been increasingly connected, enabling remote control and cloud storage of data. At the same time, acoustic detection technology has been expanding its applications in many fields such as power equipment detection, high-temperature non-destructive testing, and ultrasonic microscopic detection. Emerging technologies such as photoacoustic detection and acoustic imaging have also emerged, and it is expected to play a greater role in more fields in the future.

With the advancement of Industry 4.0 and intelligent manufacturing, the combination of new productive forces and acoustics is becoming an important force to promote industrial innovation and high-quality development. The deep integration of acoustic technology and artificial intelligence has shown unique advantages in specific scenarios such as ultrasonic monitoring and arc sound signal analysis in production line finished product detection. In the field of equipment monitoring, acoustic monitoring technology has the advantages of non-contact and high cost-effectiveness, and can collect information related to the health status of machine operation. In environmental monitoring, acoustic monitoring technology can be used to monitor various sounds in the natural environment to assess biodiversity and ecosystem health, injecting new impetus into industrial upgrading and technological innovation.

Defects of Traditional Acoustic Methods

Manual listening detection: It is greatly affected by subjective factors, difficult to accurately identify tiny abnormal sounds, prone to missed detection and misjudgment, resulting in low detection efficiency.

Data acquisition and analysis system: Although it can improve detection accuracy and reliability, it has high requirements for sensor accuracy and signal processing algorithms, and to a certain extent, relies on manual operation and professional knowledge for result interpretation.

System Introduction

The AI acoustic detection and monitoring system consists of three modules:

Data acquisition module: Composed of four parts: sensor, data acquisition, data transmission, and terminal platform, it can collect acoustic and vibration signals, support multiple sensors, and provide high-fidelity raw data. Multi-channel synchronous measurement provides rich scene support for multi-point and multi-production lines.

Data preprocessing module: A software service deployed on the terminal platform that processes the collected data such as noise reduction and normalization to improve data availability. It uses feature extraction algorithms to extract the characteristics of sound data in preparation for subsequent classification.

AI classification module: The core module deployed on the terminal platform uses deep learning algorithms to classify acoustic signals. It uses a variety of neural networks to complete the training of classification tasks and selects the best-performing model for application.

System Advantages

1.Low Threshold and User-Friendly

No professional knowledge required: Traditional acoustic analysis requires profound acoustic knowledge, while the AI system simplifies operations, allowing users to get started without a professional background. The AI algorithm automatically processes complex acoustic data, so users do not need to master professional knowledge such as Fourier transform, reducing the use threshold.

Simple and easy-to-operate interface: The system interface is designed to be simple and intuitive, with a simple operation process, allowing users to master it quickly. It provides a visual operation interface, and users can complete data classification tasks by dragging and dropping, improving user experience and efficiency.

Adapt to a variety of user scenarios: Suitable for users in different industries, such as industrial quality inspection, environmental monitoring, etc., without additional training. The system supports multiple languages and multiple devices, making it convenient for users in different regions and industries.

2.Accuracy and Reliability

High classification accuracy: High sound classification accuracy, which can accurately identify acoustic signals in different working conditions and states. When the training data is high-quality, excellent results can be achieved with a small sample size. Traditional methods are greatly affected by human factors, and the AI system can automatically identify tiny differences to improve monitoring accuracy.

Strong adaptability: The AI system can automatically learn new data, adapt to different environments and scenarios, and maintain high-precision results. Traditional methods require manual parameter adjustment, while the AI system can automatically optimize the model to adapt to changes.

High reliability: The AI system runs stably and has high reliability, and can run stably for a long time. Traditional methods are affected by human subjective factors, with large differences, low reliability, and easy to make mistakes.

3.High Efficiency and Cost Saving

Fast processing speed and high efficiency: The AI algorithm can quickly process a large amount of acoustic data, which is several times more efficient than traditional methods. Traditional methods require manual frame-by-frame analysis of acoustic signals, while the AI system can complete the classification in a short time.

Save labor costs: Reduce the workload of manual analysis, reduce labor costs, and improve the operational efficiency of enterprises. Enterprises do not need a large number of professional acoustic analysts, and the AI system can automatically complete most of the work.

Reduce hardware requirements: The AI system has low hardware requirements, and ordinary equipment can run, reducing hardware investment costs. The auscultation model does not require cloud computing or server clusters and can run on local equipment.

Hardware Composition

1.Small System

USB measurement microphone kit: MU2121 USB measurement microphone kit integrates a 1/2-inch prepolarized free-field measurement microphone, microphone preamplifier, 24-bit A/D, and USB interface. It transmits measurement data to the PC or mobile terminal through a USB cable. It contains two channels of low sensitivity and high sensitivity, and is used with test software for high-performance noise measurement.

Laptop: A lightweight AI model can be deployed on a common laptop, and a set of collection, training, and application systems can be quickly built with a USB microphone. It is suitable for initial testing stages or portable and quick testing verification scenarios.

2.Large System

Multi-channel data collector: Q041-H-T-2 multi-channel data collector supports up to 4 channels of data input at the same time and access to various IEPE-type sensors. It supports a maximum sampling rate of 192kHz, meeting the frequency band requirements of most acoustic and vibration signals.

Microphone kit: Allinby independently develops and produces various types and specifications of microphones. IEPE-type prepolarized microphones can be directly connected to the Q041H-T-2 data collector for use.

Accelerometer: Allinby independently develops and produces various types and specifications of accelerometers. IEPE-type acceleration sensors can be directly connected to the Q041H-T-2 data collector for use.

Industrial computer/server: A high-performance platform, combined with a multi-channel data collector, can expand more data channels and larger data volume for training and application. It is suitable for detection in fixed environments such as production lines and large machinery, and can solve the problem of insufficient performance of laptops in multi-production line or multi-channel cases.

3.Distributed Cloud System

Distributed collection terminal: Composed of sensors, preamplifiers, collection modules, high-performance processors, transmission modules, and storage modules. It has edge computing capabilities, and pre-trained models can be placed in the equipment to realize the whole process of raw data collection, feature extraction, sound classification, and result reporting. It can real-time report the detection results or abnormal events to the cloud server through wireless data transmission. It can flexibly expand algorithms, and add or modify data preprocessing and feature value extraction algorithms at any time, and update pre-trained models, etc.

Cloud server: Cooperating with wireless distributed devices, it realizes edge-side computing, and the cloud receives, statistics, and displays. The computer and mobile terminal can conveniently browse the data display platform to understand the monitoring status in time. It is suitable for various complex scenarios such as mass use, dispersed use, centralized use, outdoor environment, workshop and factory building.

4.Peripheral Hardware

Anechoic chamber and anechoic box: According to the size of the customer's detection target and site conditions, customize the anechoic test environment to reduce environmental and other noise interference and improve detection efficiency and accuracy.

Fixed fixtures/tools: Customize different types of fixtures for different test targets to ensure test consistency and stability and reduce unnecessary human factor interference.

AI Acoustic Platform Software

The analysis system can intelligently identify abnormal features in the sound, such as precursor signals of equipment failure or irregular noise during operation, and then automatically trigger an alarm mechanism to notify relevant personnel in a timely manner. At the same time, the system will also store and file historical sound data for subsequent trend analysis and fault tracing. In addition, users can flexibly configure monitoring parameters and alarm thresholds through a friendly interactive interface to adapt to different application scenarios.

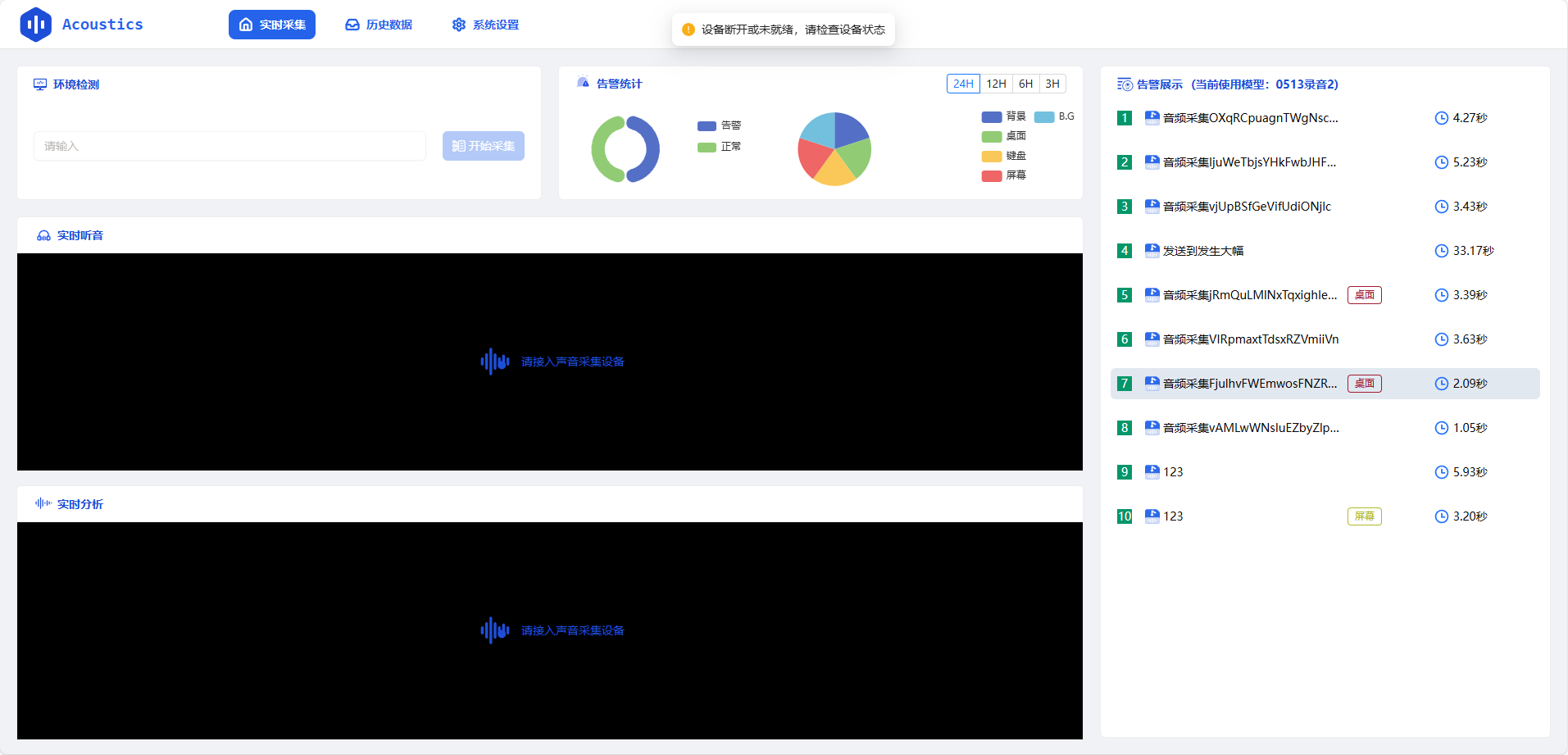

1.Real-time Data Collection and Analysis

Based on various data collection devices, it carries out all-round and uninterrupted real-time collection of monitoring targets. By using cutting-edge lightweight deep learning frameworks and efficient edge computing architectures, the system can perform millisecond-level accurate analysis and processing on real-time audio streams. The system not only has the ability to quickly identify various sound features but also can accurately detect potential abnormal events, thereby ensuring rapid response and timely processing in the face of 突发情况,effectively improving the real-time response ability and overall reliability of the system, and providing strong guarantee for the stable operation of equipment.

2.Data Visualization

The system provides comprehensive acoustic signal visualization functions, allowing users to deeply understand the characteristics of data in an intuitive way. By using a variety of graphic display means such as waveform diagrams and spectrograms, the complex acoustic signals are presented in a graphical form, which greatly improves the user's perception and understanding of the data. This visualization function not only makes the analysis process of acoustic signals more intuitive and convenient but also helps users quickly capture key information in the data in a short time.

3.Classification Result Display

The classification results will be comprehensively displayed in an intuitive and easy-to-understand way, allowing users to quickly capture the key information. Specifically, the system will comprehensively use two forms of performance, charts and text, to present the classification results in a form combining pictures and texts. The combination of the intuitiveness of the chart and the detailed description of the text can not only help users quickly grasp the overall situation but also deeply analyze each classification detail, thereby greatly improving the user's analysis efficiency and accuracy.

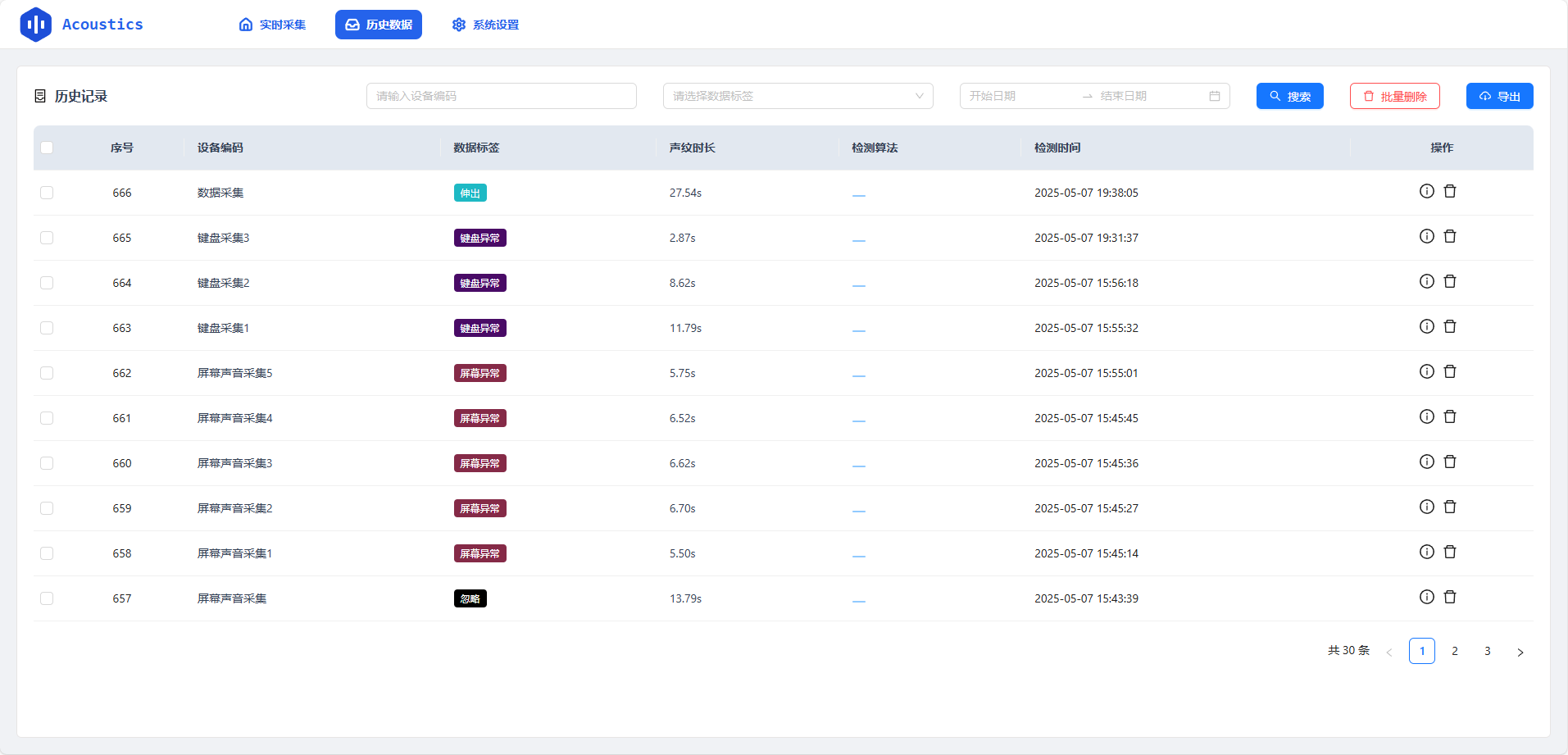

4.System Management and Maintenance

The platform comprehensively provides system management functions, aiming to provide users with a convenient and efficient maintenance and update operation experience. Specifically, the system not only supports data statistics functions, which can collect, sort out and analyze various types of data in detail but also has a data playback function, allowing users to trace back and review historical data, so as to better understand the data change trend and potential problems. In addition, the system also provides comprehensive data management functions, covering many aspects such as data storage and backup, to ensure the security and integrity of data. More importantly, the system also supports model training functions. Users can carry out model training and optimization on the data according to actual needs to improve the accuracy and adaptability of the model, so as to better meet the changing business needs. Through the comprehensive application of these functions, users can manage and maintain the system more efficiently, ensuring the stable operation and continuous optimization of the system.