Background and Current Situation

With the global increase in demand for clean energy, wind power, as one of the important renewable energy sources, has seen continuous expansion of its industrial scale. An increasing number of wind turbines are installed in various complex environments, including remote areas such as mountains, islands, and grasslands. Wind turbine blades are numerous and have long operating hours, and their reliability and stability are directly related to the normal power generation and economic benefits of wind farms. Therefore, effective monitoring means are required to ensure the healthy operation of the blades.

The operation and maintenance costs of wind farms account for a large proportion of the total cost of wind power. As vulnerable components, if blade failures are not detected and handled in a timely manner, they may trigger serious unit failures, leading to shutdown maintenance or even blade replacement, which will cause huge economic losses. Real-time monitoring of blades through means such as noise monitoring can detect problems in the early stage of failure, achieve predictive maintenance, and effectively reduce operation and maintenance costs.

Contact Monitoring Methods

Common contact monitoring methods such as vibration monitoring and fiber optic sensing require installing sensors on blades, which may damage the original structure of the blades and affect their performance. Meanwhile, the installation and maintenance of sensors are quite difficult.

Non-contact Optical Monitoring Methods

Although non-contact optical monitoring methods such as image recognition avoid physical contact with blades to a certain extent, their monitoring effects will be greatly reduced in harsh weather conditions (e.g., fog, rain, night), failing to ensure stable all-weather monitoring.

Traditional Sound Level Meter Measurement

Portable sound level meters feature simple structure, low cost, and convenient operation, but they have relatively poor accuracy and stability, single function, and cannot perform complex data analysis.

4G Wireless Monitoring Solution

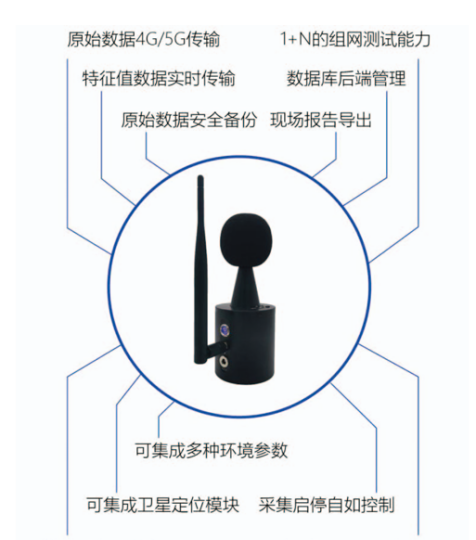

High-precision Measurement:High-precision measurement microphones collect high-fidelity sound signals in real time.

Edge Computing:Automatically extract noise characteristic values of wind turbine blades.

Wireless Transmission :Noise characteristic values of wind turbine blades are uploaded to the server via wireless 4G, getting rid of complex cable constraints.

Local Storage :Raw data is retained in local large-capacity non-volatile storage space, facilitating monitoring personnel to conduct secondary analysis of raw data of abnormal events.

Artificial Intelligence:A pre-trained model is deployed on the server side to intelligently determine whether the wind turbine noise is abnormal.

High-reliability Design:With an IP67 waterproof rating and a self-recovery mechanism, the system can be long-term deployed in harsh field environments to perform monitoring tasks.

Semi-permanent Installation:Supports external solar power supply to provide long-term battery life for field use.

Figure 1 Wireless 4G Terminal

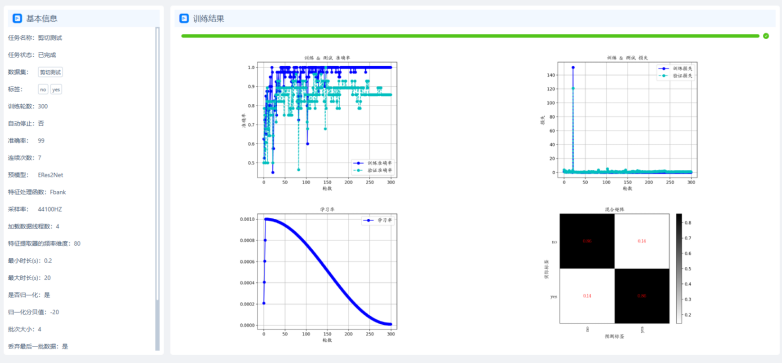

Figure 2 Server-side Model Training Results

System Introduction

The wind turbine blade noise monitoring system is designed to efficiently and accurately conduct real-time monitoring of the noise generated during the operation of wind turbine blades. Through an innovative technical architecture and advanced algorithm models, it can promptly detect potential fault hazards, ensure the stable operation of wind turbines, and enhance the overall power generation efficiency and operation and maintenance management level of wind farms.

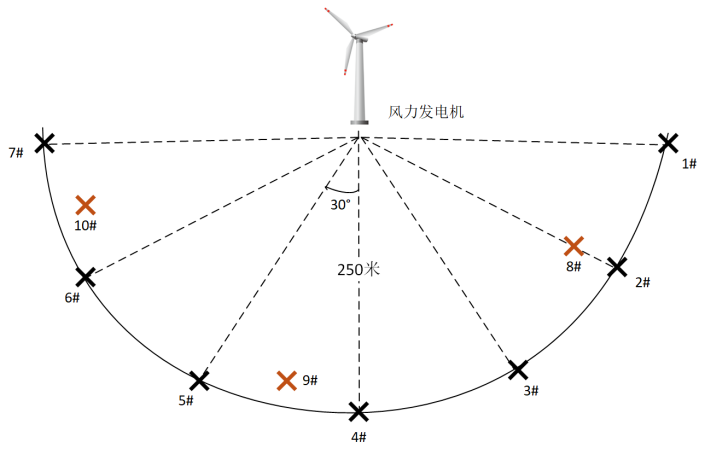

Wireless 4G terminals are distributed in the downwind direction behind the blades (as shown in the figure below: the black X indicates the monitoring points, the red X indicates the reference positions for solar energy installation, and the black solid line is the semi-circular reference line, which is not the connection between devices). Combined with the operating status and orientation data of the wind turbines themselves, the system intelligently selects the noise data directly behind the blades for judging the status of the wind turbine blades.

Figure 3 Schematic Diagram of Terminal Deployment Positions

System Architecture

Edge-side Devices:Composed of multiple distributed high-precision noise acquisition devices, which can comprehensively capture noise signals generated by blades under different wind directions. The edge-side devices are also equipped with high-performance signal acquisition and preprocessing modules, which perform preliminary filtering, amplification, analog-to-digital conversion, etc., on the collected raw noise signals, and extract noise characteristic values from them. These characteristic values will be uploaded to the server side through a wireless communication network.

Server Side:Operates an advanced AI model based on deep learning algorithms, which is trained with a large amount of historical wind turbine blade noise data and corresponding fault label data. It can automatically learn the complex association patterns between normal and abnormal noise features, conduct real-time analysis and judgment on the noise characteristic values uploaded by the edge side, accurately identify various abnormal conditions of wind turbine blades such as cracks and blade imbalance, and generate corresponding early warning information and diagnostic reports.

Core Functions

Real-time Monitoring and Data Collection:Edge-side devices conduct 24/7 real-time monitoring of wind turbine blade noise to ensure every moment of noise data is accurately captured. After preprocessing, the collected data is uploaded to the server at a stable frequency, providing a timely and reliable data foundation for subsequent analysis.

Noise Feature Extraction and Compression:The signal processing module at the edge uses advanced algorithms to extract features from raw noise signals—for example, obtaining frequency spectrum features via Fast Fourier Transform (FFT), and calculating statistical metrics like sound pressure level, noise energy mean, and variance through time-domain analysis. During feature extraction, the system compresses data to remove redundant information, retaining only feature values valuable for fault diagnosis. This not only reduces data transmission bandwidth requirements but also alleviates server-side data processing burdens, enhancing overall system efficiency.

AI Model Anomaly Detection and Diagnosis:The server-side AI model, based on a deep neural network architecture, gains powerful pattern recognition and classification capabilities through learning and training on massive wind turbine blade noise sample data. When receiving noise feature values uploaded from the edge, the model rapidly analyzes them, compares them with normal blade noise feature patterns, and quickly determines whether current blade noise is abnormal. It generates early warnings of different levels according to the severity of anomalies, providing clear fault indications and handling suggestions for O&M personnel.

Data Storage and Historical Review:The system is equipped with large-capacity data storage to recover all raw noise data from edge devices. This not only enables O&M personnel to query historical data at any time for retrospective analysis of wind turbine blade operation, but also provides abundant data resources for continuous model optimization. By mining and analyzing historical data, it is possible to identify noise variation patterns of wind turbine blades at different operation stages and under different environmental conditions, predict the occurrence trend of potential faults in advance, and formulate more scientific and reasonable maintenance plans.

Technical Advantages

High-efficiency Data Processing Capability:The application of edge computing technology enables most data processing tasks to be completed at the edge close to data sources, effectively reducing latency and bandwidth usage for data transmission to the cloud or server centers. This allows the system to analyze and respond to wind turbine blade noise in real time and at high speed. Even in large-scale wind farm environments, the system can ensure efficient operation without performance bottlenecks caused by surging data volumes.

High-precision Fault Diagnosis:The deep learning-based AI model can automatically learn complex features and patterns from massive noise data. Compared with traditional fault diagnosis methods based on empirical thresholds or simple algorithms, it offers higher diagnostic accuracy and reliability.

Flexible System Scalability:The system exhibits excellent scalability whether adding new wind turbine blade monitoring points or upgrading existing system functions (e.g., introducing new noise feature extraction algorithms or optimizing the AI model structure). Both edge devices and server-side software can be easily modularly upgraded and expanded to adapt to the continuous expansion of wind farm scales and the continuous updating of wind turbine technologies.

Strong Environmental Adaptability:Edge-side noise sensors and related devices adopt industrial-grade designs with high protection levels and wide temperature adaptability ranges, enabling them to withstand harsh natural environmental conditions in wind farms, such as high/low temperatures, high humidity, and strong sandstorms. This ensures the system can operate stably and reliably throughout the lifecycle of wind turbines, continuously providing accurate noise monitoring data.

System Benefits

Improved Turbine Reliability and Availability :By promptly and accurately monitoring abnormal noise in wind turbine blades, detecting potential faults in advance, and addressing them, the system effectively prevents sudden turbine shutdowns due to faults. This reduces downtime caused by maintenance, enhances turbine reliability and availability, and thereby increases power generation and economic benefits for wind farms.

Reduced Operation and Maintenance Costs:The precise fault diagnosis function enables O&M personnel to perform targeted maintenance and repairs on turbine blades, avoiding unnecessary equipment disassembly and inspections, and reducing waste of labor and materials. Meanwhile, through historical data analysis and prediction, preventive maintenance plans can be reasonably scheduled, further cutting O&M costs and improving maintenance efficiency.

Ensured Safe Operation of Wind Farms:Turbine blade failures may lead to serious safety accidents, such as blade breakage and ejection. This monitoring system can issue timely warnings at the initial stage of a fault, providing sufficient response time for wind farm O&M personnel to take corresponding measures. This prevents accidents from occurring or escalating, ensuring the safety of personnel and equipment in wind farms and safeguarding the interests of the surrounding environment and the public.