The equipment status monitoring system is an intelligent system that integrates sensors, data acquisition and analysis technology. It is used for real-time monitoring of the operating status and key parameters of large equipment (such as generator sets, industrial machinery, etc.). By collecting data from equipment, the system can identify anomalies and potential faults, provide real-time warning and fault diagnosis, help optimize equipment maintenance plans, reduce equipment failure risks, extend equipment lifespan, and improve equipment reliability and production efficiency. The online monitoring system for the status of large-scale equipment has important application value in the industrial field, providing key support for enterprises to achieve intelligent operation and maintenance management and sustainable development.

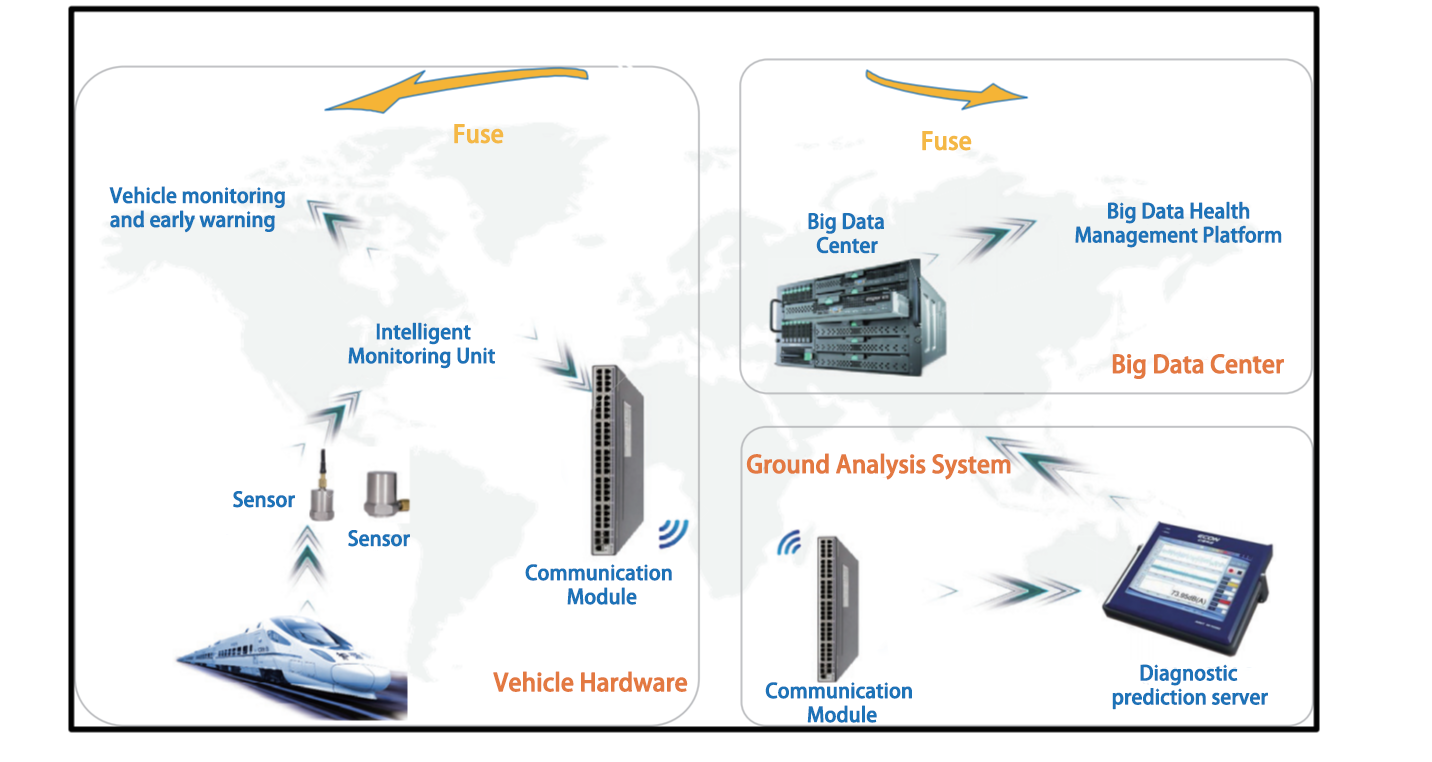

The equipment status monitoring system utilizes multi-dimensional collection methods and advanced technologies such as IoT and big data to construct a standard digital model of the equipment. At the same time, it integrates AI algorithm models such as mechanism models, intelligent algorithms and machine learning to achieve intelligent faults warning, diagnosis, and life prediction of equipment, and achieve full lifecycle management of equipment. The platform is equipped with self-learning mechanism, which can automatically iterate and upgrade algorithm models, continuously optimize the accuracy of equipment models, intelligent warning and diagnostic models, gradually form an industry replicable expert knowledge base, and improve the standardization and specialization level of industry equipment operation and maintenance management.

·Collect multiple types of data to achieve comprehensive monitoring of equipment;

·The data analysis results are displayed in real-time on the large screen, and the device status can be viewed at any time;

·Accurate measurement, reliable data, easy installation and maintenance;

·By comparing the results of rich data calculations, analyze the actual development trend of the state and understand the safety status of the monitoring object;

·Cooling Tower of a certain Gas Thermal Power Plant in Beijing;

·The cooler of Huaneng Dongshan Thermal Power Plant;

·Beijing Poly Theatre;