Beijing Allinby acoustic temperature measurement solution appeared in the "2024 Smart Power Plant Forum" to help the intelligent monitoring and management of the furnace temperature field in the power plant

At the just-concluded "2024 Smart Power Plant Forum", Beijing Allinby Technology Co., Ltd. became the focus of industry innovation with its autonomous and controllable acoustic furnace temperature measurement solution. This technology has not only attracted the attention of industry experts and representatives of power generation groups at the forum, but also indicates the new direction of intelligent transformation of the power industry.

The forum, co-sponsored by North China Electric Power University and other institutions, was held in the spring city of Jinan from April 25 to 26. The forum conducted an in-depth discussion on the development of smart power plants under the new energy system, focusing on the directions of safety control, AI large model, intelligent equipment, and multi-energy complementarity, and jointly discussing the future development of smart power plants under the new energy system.

![]()

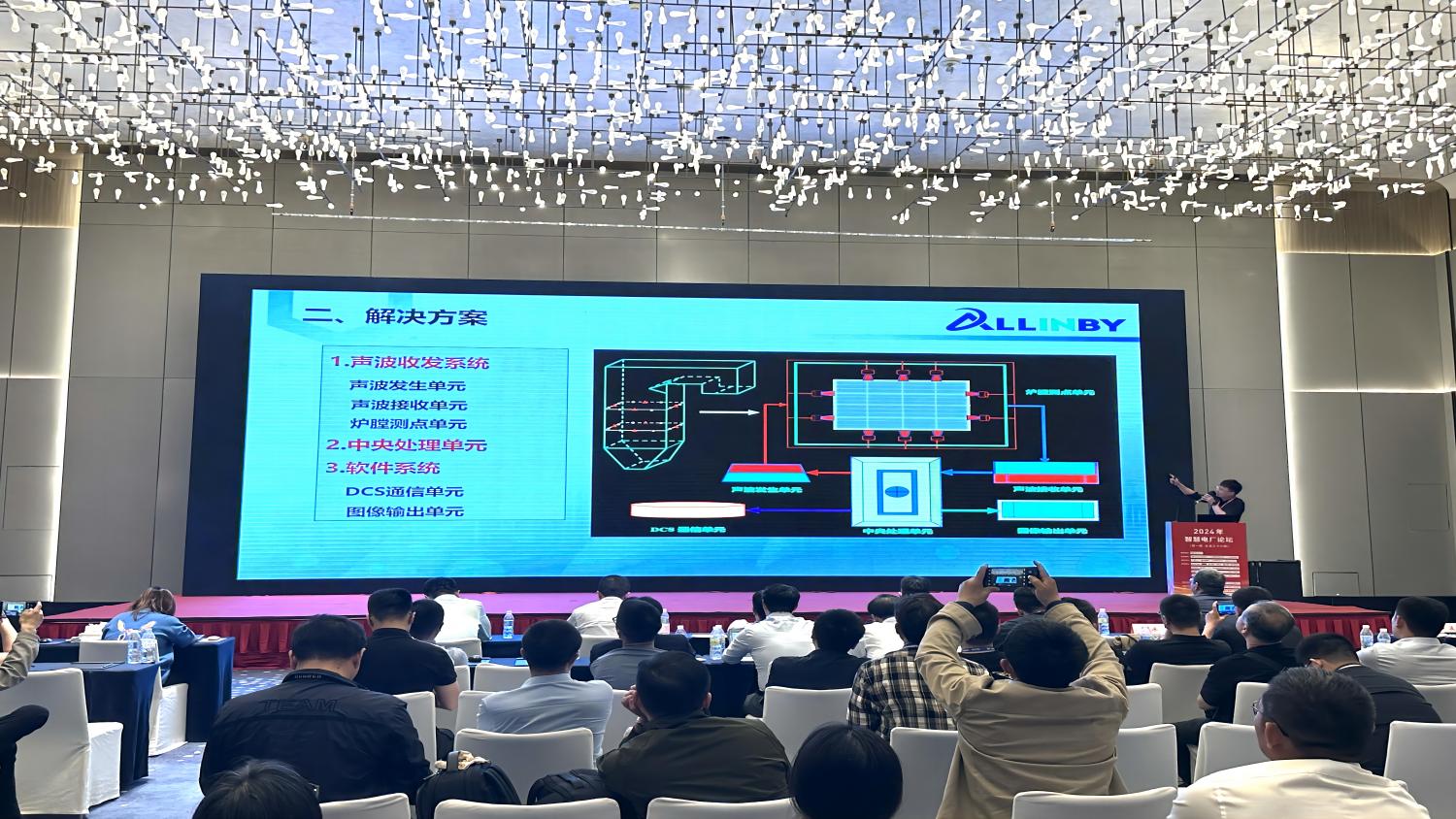

In the smart equipment sub-forum on the afternoon of April 26, Ren Xiaofei, technical expert of Beijing Allinby , brought a speech of "Acoustic furnace temperature measurement Solution", he said that with the global energy structure transformation and the deep reform of the power market in the context of the planning, construction and implementation of smart power plants, has begun to deeply integrate new technologies and new products of energy and power. And cloud computing, big data, artificial intelligence and other digital and intelligent technologies.

Ren Xiaofei pointed out in his speech that with the transformation of the global energy structure and the deep reform of the power market, the construction of smart power plants has become an urgent need for the industry. After years of joint research and development by the expert team of Beijing Auyinbei and the College of Energy, Power and Mechanical Engineering of North China Electric Power University, the acoustic furnace temperature measurement solution has been able to reflect the temperature field distribution in the furnace in real time and intuitively, breaking the technological monopoly of international companies in China.

This solution has the characteristics of complete autonomous control, high-precision monitoring, real-time online monitoring and early warning and intelligent management. All hardware and software are 100% domestic, ensuring technical independence and security. The high precision monitoring capability of the scheme can achieve the path temperature accuracy of less than 1%, the temperature resolution of 0.1℃ at normal temperature and 3℃ at hot state, providing reliable temperature monitoring data for the power plant. Moreover, the visual interface can present the combustion intensity of furnace section, flame eccentricity coefficient, isotherm chart and data intuition in real time, so as to realize intelligent management and support. Data show that after the adoption of this scheme, the boiler long-term optimization operation, can reduce the combustion efficiency of 0.5%, the unit power supply coal consumption can be reduced by at least 0.5g/kWh, while reducing carbon dioxide emissions, installed capacity of 600MW coal-fired power plant, annual carbon dioxide emission reduction of not less than 260,000 tons.

At present, the acoustical furnace temperature measurement solution of Beijing Allinby has been successfully applied in more than ten power plants such as National Energy Group and Huadian Group. Ren Xiaofei said that we have been focusing on the research and exploration in the field of acoustics and vibration, accumulated technology for more than 10 years, and served more than 2000 customers, covering more than 30 countries and regions. The company will continue to deepen the research and development of acoustic temperature measurement technology and program optimization, to provide more intelligent and efficient monitoring solutions for power plants, and help power plants achieve safe production and sustainable development.